Customer portals: central communication platform and automated asset management

The mechanical engineering industry is undergoing radical change. In addition to short-term product business, companies need to tap into longer-term revenue streams. As a result, the focus is shifting to the customer’s installed machine base. This is because machines that have already been sold can generate high-margin service revenue in the long term. The prerequisite: digitalization – but with a plan. However, a study by the Friedrich Ebert Foundation shows that small and medium-sized companies in particular often struggle with digitalization. Where to start, what to implement and with whom? Other reasons for this reluctance are concerns about data security and the shortage of IT specialists. According to the study, there is also a lack of awareness of the concrete economic opportunities of digitalization.

Touchpoints with customers

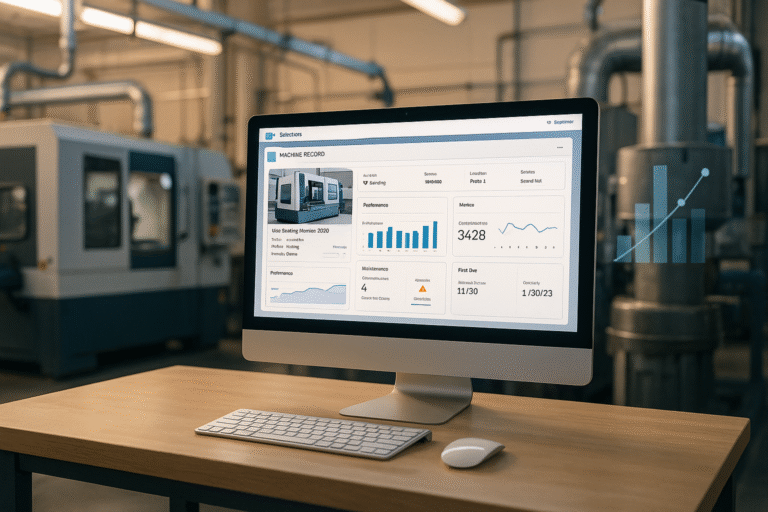

The challenges are similar for many companies and so are the steps towards digitalization. This takes place at two touchpoints: on the one hand with the customer’s employees, and on the other at the machine. Customers must be able to communicate directly with the manufacturer via platforms, and their inquiries must be processed quickly via ticket systems – without media disruptions and in self-service. At the same time, it should be possible to digitally monitor the status of machines and control them at any time. The central hub for this is a customer portal that brings together information about products, services and the customer relationship and serves as the nucleus for further digitalization steps. However, the term customer portal may be misleading, at least if it is only understood as a shop window:

A customer portal enables efficient and direct communication between customers and companies and offers features that digitally enhance the physical product and, in particular, improve the customer experience and machine performance.

The front end is just the tip of the iceberg

What the customer sees – the front end – is just the tip of the iceberg. A good customer experience and an offering that clearly differentiates itself from the competition are the external success factors. Hidden from the customer is the back end, which ensures integration into various IT systems and a largely automated data flow and therefore high efficiency. The machine manufacturer should be careful not to become technologically dependent. They need a customized solution that integrates seamlessly into the existing IT systems. The customer portal should adapt to the IT and not the other way around. The overarching goal is clear: a customer portal specifically for mechanical engineering should increase machine performance for the machine operator. Many machine manufacturers are currently asking themselves when they should start setting up a service platform. The answer is simple: now. For new business models such as equipment-asa-service, such digital service platforms are indispensable because they make scalability possible in the first place through digitalization and automation. Regardless of which features are added in which order – at the core, it is always about the machine and its performance.

Digital service platforms are indispensable for business models such as equipment-as-a-service because they enable scalability in the first place through digitalization and automation. At its core, it is always about the machine and its performance.

Here are a few ideas of what a service portal should be able to do:

- Order management

- Webshop and identification of spare parts

- Product documentation and resources

- Support and service

- Remote Support

- Collaboration and communication

- Identity Management

- Extension of the physical product

- Knowledge base

- Digital twin

- Predictive maintenance

- Equipment-as-a-Service models

Asset management is therefore the foundation of a service platform in mechanical engineering. In order to optimize performance, all relevant information and assistance must be available to the customer. The interoperability of the machines and the ability to integrate the data are also important, which requires an API. The classic solution for such a service is predictive maintenance. It significantly increases the performance of a machine and saves time and money. Above all, it saves the customer from unpleasant surprises.

Validate feature ideas on the market first

However, companies should not rush into anything. For the ideal customer experience and clear added value, feature ideas often need to be validated on the market first because they are very customer-specific. And not everything has to be implemented right from the start; features can be added gradually.

- Start with a simple information portal about the assets

- Webshop for spare parts

- Information on orders

- Interactive service such as remote support or augmented reality

- Provision of a digital twin and thus integration into third-party ecosystems

- Functions for predictive maintenance, additional software features, machine performance optimizations

All theory is gray. Here is a successful example from a medium-sized mechanical engineering company:

He has set up a platform that centrally bundles all information on products, customers and their current orders. Customers have access to all important documents relating to the products, from technical documentation, brochures, videos, certificates, product descriptions and operating instructions to a digital twin for the current generation of machines. A spare parts store is also integrated into the portal. The customer is currently preparing to exchange and analyze machine data for predictive maintenance.

The company relies on a standard platform that impresses with its open interfaces, simple expandability with low-code tools and high scalability. This technology-oriented approach made it possible to meet individual requirements and still ensure rapid implementation.

Thanks to this flexible and future-proof approach, the machine manufacturer was able to implement the basic platform in just six months. In the medium term, the company plans to launch the portal globally and offer customers worldwide access. The strength of the solution lies in its adaptability: it is not static, but can be continuously adapted to local conditions and new developments. Thanks to the use of established standards, machine and plant manufacturers remain independent and well equipped for the challenges of digital transformation.