Digitize service processes: Step-by-step

Did you know that the service business in mechanical engineering often generates margins twice as high as machine sales? By digitizing your service processes, you can not only increase your efficiency, but also significantly improve customer satisfaction.

The 5 most important steps at a glance:

Analysis of current processes: Identify weak points such as long response times or inefficient use of resources.

Set up a central platform: Use cloud and IoT technologies for automation and real-time monitoring.

Organize data: Structure asset and customer data to make informed decisions.

Automate processes: Implement predictive maintenance and automated ticket systems.

Measure and optimize results: Define KPIs such as first-time resolution rate and analyze data to drive continuous improvement.

Why this is important:

With a clear strategy and modern tools such as AI and IoT, you can minimize downtime, use resources more efficiently and secure a competitive advantage.

Steps towards digitalization and goals - process analysis and optimization using the example of

The video “Steps to digitalization and goals | Process analysis and digitalization” by OrganisationsEntfaltung uses a practical example to show how processes can be systematically analysed and digitalized. It emphasizes the importance of clear target definitions and a step-by-step approach in order to successfully implement digitalization projects. The benefits of a detailed process analysis are highlighted in order to identify optimization potential and introduce targeted digital solutions.

In the context of mechanical engineering, this approach can be particularly valuable in the service sector: The digitalization of service processes, such as the use of digital maintenance logs or remote maintenance tools, can increase efficiency and customer satisfaction. A structured process analysis helps to identify specific requirements and implement suitable digital solutions.

Step 1: Analysis of current service processes

A detailed analysis of your existing service processes is the first step in effectively driving digitalization forward.

Identify bottlenecks in processes

Use key figures to identify weak points in your processes:

Response time: How long does it take from the fault report to the service call?

Resource utilization: How efficiently are technicians and spare parts deployed?

Information flow: Are there delays due to manual input or disconnected systems?

You should then take a closer look at your IT systems and existing data.

Check existing systems

Analyze the IT systems used and the quality of your data:

Data quality: Is the data complete and up-to-date?

Integration: Can the systems be easily connected to cloud or IoT solutions?

Based on these findings, you can plan the next steps for digitization.

Define important digitization areas

Focus on projects that offer great potential for optimization and can be implemented quickly. Involve service technicians at an early stage to gain practical insights and advice on suitable solutions.

Step 2: Set up central service platform

After analyzing your existing processes (step 1), the next step is to set up a central platform that serves as the heart of your service processes.

Select service platform

Based on the findings from the process analysis, select a platform that meets your most important requirements. The focus should be on criteria such as missing interfaces or slow response times. According to a study, over 40% of companies have difficulties with system interfaces.

A suitable platform should offer the following functions:

AI-supported condition monitoring for predictive maintenance

IoT real-time data acquisition to evaluate machine and process data live

Customizable workflows that can be adapted to your specific processes

Automated resource planning to work more efficiently

Connecting business systems

A good example of the benefits of a fully integrated platform is provided by a Swiss mechanical engineering company, which can now plan 85% of its service orders automatically and react flexibly to changes [1].

Here is an overview of possible improvements:

Order acceptance: increase of 30

Order planning: efficiency increase of 50

Workload of the sales force: reduction by 20

First-time fix rate: improvement of 28

In addition, you should set up a self-service portal to relieve both customers and your internal processes.

Set up customer portal

A self-service portal enables your B2B customers to complete routine tasks independently and at any time. The following functions should be integrated:

Digital appointment scheduling for maintenance and repairs

Online catalogs for easy ordering of spare parts

Access to technical documentation and maintenance instructions

Live chat support for quick help with problems

Such a portal not only ensures uniform service standards, but also reduces the workload of your service employees. The connection to your ERP system is important to ensure a smooth flow of information.

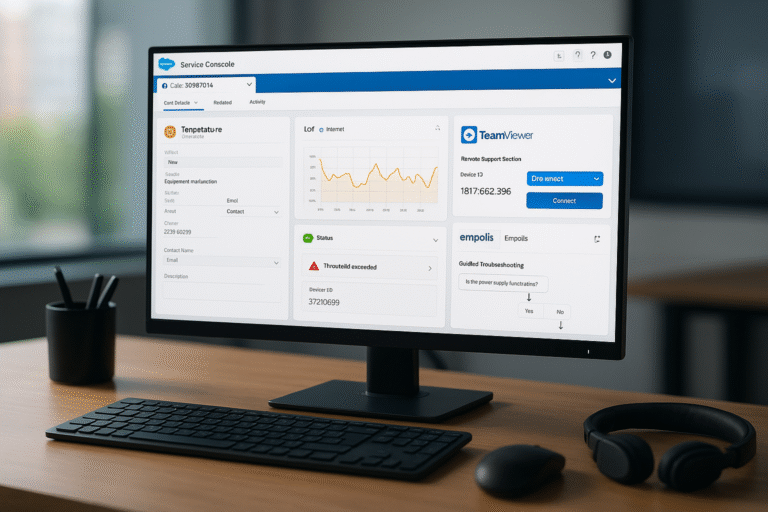

Customer service and proactive management of the installed base combined on the Salesforce platform

We solve the challenges of service in mechanical engineering on the leading Customer 360 platform from Salesforce: supplemented by a web store for spare parts, a self-service portal with information on the assets, functions for managing the installed base and AI tools that automate service and sales processes. No new silos, no exotic technologies or skills, scalable as required and with a large ecosystem of partner solutions.

Step 3: Organize service data

Now that you have set up a central platform (step 2), it is time to organize your service and device data so that it can be used efficiently.

Structure system data

To enable data-driven services, your system data should be well structured:

-

Standardized machine data formats facilitate recording and storage.

-

Digital device files contain all information on maintenance, repairs and operating history.

-

Key performance indicators (KPIs) such as operating hours and capacity utilization provide the basis for well-founded decisions.

With a clear structure in the system data, you can seamlessly move on to standardizing customer data.

Standardize customer data

A standardized structure of customer data ensures more efficient service processes:

-

Central storage and standardized templates guarantee complete and consistent customer data.

-

Mobile access to this data enables technicians to call up the information they need at any time.

-

Digital records document all interactions with customers seamlessly.

Set up IoT monitoring

By implementing IoT monitoring, you can make your services more proactive:

-

Sensors record real-time data to continuously monitor critical parameters.

-

AI-supported analyses help to precisely predict maintenance requirements.

-

Automatic notifications alert you if deviations or limit values are exceeded.

This allows you to use IoT data in a targeted manner to optimize service operations:

-

Predictive maintenance minimizes unplanned downtime.

-

More efficient resource planning ensures needs-based deployment.

-

Higher system availability is achieved through timely interventions.

Ensure that IoT monitoring is seamlessly integrated into your service platform to realize its full potential.

Step 4: Introduce process automation

The structured service data from step 3 can now be used to introduce automated processes. The aim is to increase efficiency, minimize errors and create a better customer experience.

Automate service tickets

IoT sensors can be integrated into a central ticket system to automatically detect and process faults. This has clear advantages:

-

Prioritization according to machine data: Tickets are sorted intelligently according to urgency.

-

Real-time updates: Status changes are made automatically and without delay.

-

Direct assignment: faults are immediately forwarded to the responsible technician.

Set up predictive maintenance

Predictive maintenance makes maintenance more efficient and demand-oriented. Key points:

-

Detection of wear patterns: real-time analyses identify problems before they occur.

-

Demand-oriented planning: Maintenance is carried out exactly when it is needed.

-

Conserving resources: Precise predictions optimize the use of personnel and materials.

How it works:

-

Sensor data is collected and calibrated.

-

Wear patterns are analyzed using machine learning.

-

Maintenance plans are based on the real-time data obtained.

Use remote service

With remote service solutions, many problems can be solved without the need for technicians to be on site. These options are available:

-

AR–Remote maintenance: experts provide visual support in real time.

-

Digital instructions: Maintenance documentation is available at all times.

-

Remote access: Machine data can be analyzed and controlled remotely.

Advantages at a glance:

-

Immediate help without travel time.

-

Savings on travel and logistics costs.

-

Round-the-clock support and lower CO₂ emissions.

In the next step (step 5), key figures are defined, results are analyzed and the team is trained accordingly.

Step 5: Measure and improve results

Define key performance indicators

|

Key figure |

Description |

|---|---|

|

First-time fix rate (FTFR) |

Percentage of problems solved on the first visit |

|

Average repair time (MTTR) |

Average time required for a repair |

|

Uses per day |

Number of customer visits per technician |

|

Technician-dispatcher ratio |

Ratio of technicians to dispatchers |

These key figures help you to analyze your data in a targeted manner and identify weak points.

Analyze performance data

-

Machine data: Check fault patterns and maintenance intervals to detect problems at an early stage.

-

Employee performance: Compare repair times and success rates to evaluate efficiency.

-

Route planning: Analyze travel times to optimize routes and save time.

Train teams and adapt processes

-

Technical skills: Teach how to use digital tools and analyze data.

-

Soft skills: Train customer interaction, conflict resolution and intercultural communication.

-

Process understanding: Promote cooperation between departments to improve processes.

Compare the first solution rate with the number of daily assignments to find out how time expenditure and solution rate are related. This allows you to make targeted improvements.

These steps set the continuous improvement process in motion. If necessary, you can return to step 1 at any time to adjust the strategy.

Conclusion

The five steps described help to noticeably improve service quality and efficiency. The following factors play a central role here:

Cloud-based service platforms: They enable centralized control and better scalability.

IoT and AI-supported predictive maintenanceEarly fault detection minimizes downtimes.

Flexible maintenance contracts: These offer customized solutions for different customer needs.

Systematic knowledge management: The structured handling of knowledge promotes faster problem solving.

Continuous KPI analysis and team training: Regular evaluations and training ensure long-term improvements.

Digitalization is not a closed process. Continuous KPI analyses, team training and adjustments to new requirements will keep your service competitive.

Rethinking service processes: greater efficiency with IoT, AI and self-service

Find out how logicline’s extensions for Salesforce – especially for manufacturers of plant and machinery – can revolutionize your service processes with IoT, AI and self-service solutions. Find out more now and fully exploit service potential!