How the integration of knowledge management simplifies service

Knowledge management makes service faster, more efficient and more customer-friendly.

Time savings: Employees can access information up to 35% faster.

Cost reduction: companies with 4,000 employees save up to USD 2 million per month.

Customer satisfaction: 83% of customers expect quick responses, 72% remain loyal if the service is good.

Problem solving: Information silos are broken down, knowledge gaps are closed and machine downtime is reduced.

Central databases, AI and IoT are used to optimize service processes, minimize downtimes and increase efficiency. Companies such as Siemens and Orvis show how these approaches work in practice.

Conclusion: Knowledge management is the key to better service, more satisfied customers and lower costs.

Integration of a portal for service technicians at Carl Zeiss Meditec AG

Taking service to the next level: A knowledge management portal was introduced at Carl Zeiss Meditec to make service manuals and troubleshooting guides available for troubleshooting.

Frequent service problems in mechanical and plant engineering

In mechanical and plant engineering, scattered sources of information and an inadequate exchange of knowledge slow down efficiency and impair customer satisfaction.

The figures speak for themselves: 58% of employees waste at least one hour a day struggling through outdated document management systems [6]. At the same time, employees spend almost 20% of their working time searching for information alone.

Machine breakdowns are an expensive problem. In the mining industry, the average cost per breakdown is USD 180,000, which can cost the industry up to USD 10 billion a year [5]. In addition, mining companies spend 35-50% of their annual budgets on machine maintenance [5].

Another problem is the ageing workforce: in 2020, almost a quarter of employees in the manufacturing industry were over 55 years old [3]. When they retire, they often lose valuable experience that is rarely documented. These challenges lead to specific knowledge gaps, which are examined in more detail below.

Identify knowledge gaps

Knowledge gaps are often caused by incomplete repair data and inconsistent documentation. According to McKinsey, companies could achieve a 30-35% increase in efficiency through a more precise document search.

One example: Siemens Digital Industries has used AI-supported knowledge management to significantly reduce the time spent searching for information and increase the reusability of expertise, as CEO Cedrik Neike reports.

10-15% of all inquiries to service desks result from missing or difficult-to-access documentation. Service technicians are then faced with complex systems without having the necessary information to hand. In addition to these gaps, a lack of knowledge sharing further exacerbates the problems.

Problems due to a lack of knowledge exchange

Poor knowledge sharing leads to longer downtimes, lower productivity and dissatisfied customers. 47% of respondents report that information is scattered across different apps [2]. The result? Employees waste time by developing processes twice or failing due to bottlenecks [9].

Georgia-Pacific has tackled this problem with generative AI. Product Manager Carter Smith explains:

“The long-standing problem of knowledge loss affects the entire manufacturing sector. Generative AI helps us take proactive steps to solve it. As experienced employees retire, implementing a reliable tool with perfect memory strengthens our workforce and helps us gain and maintain our competitive advantage.” [7]

Ryan Holbird, Senior Manager for Digital Transformation at Georgia-Pacific, adds:

“Using generative AI to bring together information from different sources for quick and easy answers was a game changer for us. It’s like having a digital expert who is always there and ready to help both new and experienced operators find the right answers quickly.” [7]

Another obstacle is the resistance of employees to share their knowledge. Although 75% of organizations recognize the importance of knowledge management, only 9% are actually able to implement this goal effectively [2]. A central knowledge management system could help here by pooling information and facilitating sharing.

Tools for the integration of knowledge management

Today’s tools combine platforms with AI and IoT to make service processes more efficient. They provide service teams with the information they need quickly and accurately – exactly when they need it.

An interesting figure: 86% of service professionals say that customer expectations are higher than ever before, and 78% note that customers are under time pressure. At the same time, 61% of customers prefer self-service options and 65% use knowledge bases as their preferred source of information [12]. Below we take a look at key tools and their areas of application.

Salesforce Knowledge and Empolis Service Express

Both Salesforce Knowledge as well as Empolis Service Express offer an ideal solution for industrial knowledge management needs. Salesforce Knowledge acts as a central platform and covers all basic functions. Empolis Service Express uses decision trees, can also be used from other environments and is already supplemented with specialized functions for mechanical and plant engineering.

Lightning Knowledge integrates directly into the Salesforce platform [13]. This allows companies to seamlessly integrate their service processes into existing CRM systems.

Empolis Service Express organizes service knowledge in a structured way and can be easily integrated into systems such as SAP, Microsoft Dynamics and also Salesforce [11]. Companies such as ABB, BMW, Bosch, Carl Zeiss Microscopy, Homag and Kuka already rely on these solutions [11].

An example from practice: Internet Creations implemented a public knowledge database for Solarwind’s MSP within a month. The result? Over 1,000 cases were successfully processed [13].

Using AI and IoT for knowledge management

AI-supported tools and IoT sensor data are revolutionizing knowledge management. They help to predict equipment failures, optimize maintenance schedules and extend the service life of machines. According to forecasts, global AI investments will increase from 307 billion US dollars (2025) to over 632 billion US dollars (2028) [15]. At the same time, 18.8 billion IoT devices are expected to be connected by the end of 2024 – an increase of 13% compared to the previous year [15].

With AI, companies can significantly increase their efficiency: forecasting errors are reduced by up to 50% and lost sales due to stock shortages are reduced by up to 65% [16]. In customer service, organizations report a 35-55% reduction in processing time, 25-40% lower operating costs and a 20-35% increase in customer satisfaction [14].

Success stories underpin these figures: General Motors was able to reduce unplanned downtime through predictive analytics [15]. IBM saved $160 million during the COVID-19 pandemic with AI-powered supply chain solutions while achieving a 100% order fulfillment rate [16]. Electrolux reduced the resolution time for IT problems from three weeks to one hour, saving over 1,000 hours per year [16].

Security and compliance requirements

Protecting sensitive service data is essential. Data breaches cost compliant companies an average of 5.65 million US dollars, while non-compliant organizations have to spend 2.3 million US dollars more [17].

Interesting: 82% of all data breaches have a human origin. This shows how important clear security guidelines and training are. Nevertheless, only 18% of companies have linked security risks to compliance activities [17].

Empolis Service Express meets the highest security standards and is certified according to ISO 27001, ISO 27017 and ISO 9001 [10]. These certificates guarantee the protection of sensitive data in accordance with international standards.

For a solid security strategy, companies should rely on SOC 2-compliant providers, clearly define access rights and carry out regular training. In addition, the monitoring of suspicious activities and well thought-out software integration are among the cornerstones of a successful implementation. In this way, companies create a secure basis for their knowledge management processes.

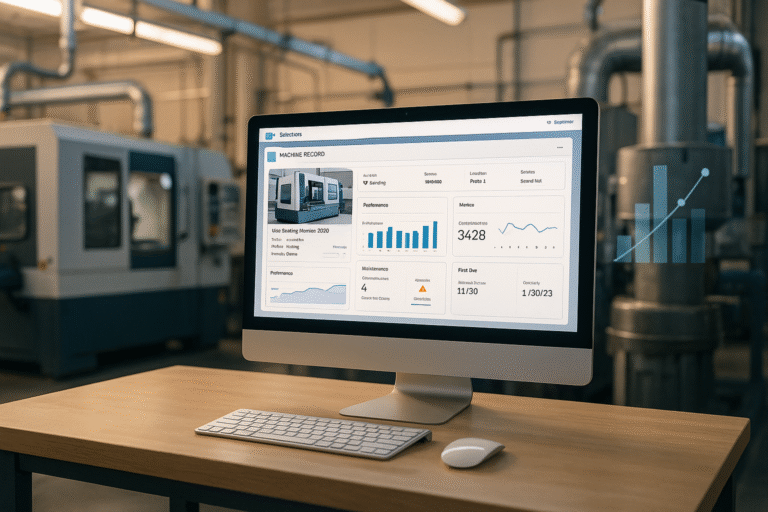

IoT asset management in Salesforce from logicline

Today, your customers expect self-service portals that offer them quick access to documentation or spare parts. At the same time, your internal processes, from resource planning to IoT-supported maintenance, need to mesh perfectly. With platform solutions such as Salesforce and our complementary modules, we create a seamless connection between your customers, your installed base and your teams.

Steps for implementing knowledge management

The integration of successful knowledge management requires a well thought-out approach. Here are practical steps to effectively implement knowledge management and optimize service processes in the long term.

Create a central knowledge database

The first step is to analyze existing information flows in order to identify knowledge gaps [19]. Clear objectives, available resources and KPIs should then be defined [19]. An impressive example: Giltner Logistics was able to reduce the training time for new employees by 50% in 2023 after introducing a central knowledge management platform [20]. Virgin Mobile also increased its self-service rate by 40% through the use of Helpjuice [18].

For intuitive use of the database, it is important to create a clear structure. Main categories, subcategories and tags help to classify the content [12]. Different departments should contribute their expertise in order to create the content together [18].

A user-friendly design with powerful search functions, clear navigation and AI-supported tools makes all the difference [12]. Article tags and internal links make orientation even easier [18].

Regular quality checks and a defined optimization plan guarantee that the content remains up-to-date and relevant [12][19]. As soon as the central knowledge database has been set up, technological data sources can be integrated.

Linking IoT data with knowledge systems

By linking IoT data, faults can be detected in real time and preventive maintenance measures can be initiated [21]. For example, a large industrial equipment manufacturer used AWS IoT Core, AWS IoT SiteWise and Amazon SageMaker to analyze sensor data in real time and predict machine failures. The result? 25% less downtime, 30% lower maintenance costs and a longer equipment lifespan [22].

Standardized protocols and frameworks ensure smooth data exchange [21]. Cloud-based platforms offer flexible and cost-efficient solutions [21].

Other successes: An automotive manufacturer reduced unplanned maintenance by 40%, while a mining company reduced downtime by 35% [22]. An AdaBoost machine learning model showed with 92% accuracy how effective real-time classification of machine stops can be [23].

For fast data processing on site, the use of AWS IoT Greengrass is recommended to minimize latency times [22]. At the same time, AWS IoT Device Defender protects the devices, while integration with ERP and MES systems enables standardized operational management [22]. With the technical basis in place, the next step is to train employees.

Train service teams in knowledge tools

Targeted training of service teams is crucial. Customized training methods increase effectiveness [25]. Interactive approaches such as workshops and simulations promote the practical exchange of knowledge [25]. Atlanticus was able to achieve significant improvements in efficiency and customer service in 2025 by using livepro [26].

The training should take into account both newcomers and experienced employees [28]. Ongoing support and access to resources contribute significantly to learning success [25].

Managers should be actively involved in the exchange of knowledge. In addition, rewards for committed employees are motivating and promote a cooperative work culture [27].

To stay up to date, regular workshops, webinars and online courses on trends and technologies in knowledge management can be offered [28].

Measuring success in knowledge management

Once a knowledge management system has been successfully introduced, it is crucial to continuously evaluate its performance and benefits. Only through regular analyses can the contribution to the efficiency of service processes and customer satisfaction be accurately assessed and specifically improved.

Key performance indicators

The effectiveness of a knowledge management system is determined using various key performance indicators (KPIs) that cover both quantitative and qualitative aspects [32]. The central KPIs include:

First contact resolution rate: How often can problems be resolved on first contact?

Average processing time (Average Handle Time): How long does it take to process a request?

Escalation rate: How often do requests have to be forwarded to higher levels?

Customer satisfaction (CSAT): How do customers rate the quality of service?

Metrics such as call volume, the number of remote solutions and the costs per solution also play an important role [29]. This data should be monitored regularly to evaluate system performance and enable continuous improvement [30].

Category | Metrics | Description |

|---|---|---|

Employee productivity | Time saved | Reduction in the time needed to search for information |

| Task efficiency | Better processing times and accuracy for tasks |

Cooperation | Exchange of knowledge | Frequency and quality of knowledge sharing |

| Collaboration metrics | Measurement of joint projects and their results |

Decision making | Decision quality | Evaluating the quality and impact of decisions |

| Time until the decision | Reducing the time needed to make informed decisions |

Cost reduction | Operating costs | Tracking cost savings through more efficient processes |

| Error reduction | Recording the reduction in errors and the resulting cost savings |

A look at customer expectations shows how important effective knowledge management is: 83% of customers want immediate contact, 73% prefer independent problem solving, and 91% are willing to use a knowledge database if it meets their needs [1].

System improvement through feedback

In addition to quantitative data, qualitative feedback is crucial for the further development of knowledge management systems. Regular feedback from service teams and customers provides valuable insights that can lead to targeted optimizations [33].

Examples of potential improvements include analyzing failed search queries, employee feedback and customer satisfaction scores. A practical case: The company Netfor restructured its knowledge database to better adapt it to the needs of its customers and used AI tools. The result? A 30% reduction in call volume and a 22% reduction in average handling time [33].

“I work in the evenings when some of my colleagues have already finished work. Some evenings I have to deal with questions that I don’t have an immediate answer to. Bloomfire has helped me answer customer questions promptly and accurately. It has made my job so much easier and I can provide a great customer experience.”

– Customer Service Representative, Penny Mac [1]

Modern analysis tools can monitor search trends, identify inadequate or outdated content and suggest targeted improvements [33]. User feedback often reveals where information is unclear or incomplete. Features such as predictive search provide results even before the search query is completed, helping to improve the user experience [33].

Articles that repeatedly fail to meet user expectations should be revised or replaced with more relevant content. Such continuous adjustments strengthen the service and increase customer satisfaction.

A financial aspect underlines the importance of knowledge management: inefficient knowledge sharing costs Fortune 500 companies around 31.5 billion US dollars a year [33]. At the same time, 60% of consumers actively search for answers via web self-service offerings [34].

The combination of measurable KPIs and qualitative feedback enables a comprehensive evaluation of knowledge management [31]. Regular reviews and adjustments based on ROI data are essential to remain successful in the long term [35].

Conclusion: Service transformation through knowledge management

The integration of knowledge management into service processes offers machine and system manufacturers a clear competitive advantage. Statistics show that these measures enable companies to reduce telephone customer inquiries by 45% and increase web traffic by 54% at the same time [38]. These figures illustrate the direct benefits of knowledge management.

Customer orientation plays a central role here: 89% of customers are willing to pay higher prices for better service experiences, and almost half (49%) make spontaneous purchasing decisions after positive interactions [38].

“Knowledge management is a dynamic management system for a sustainable business strategy, not just a storage capacity for accumulated knowledge. WM is also the ability to act on that knowledge. Organizations are no longer evaluated only for what they have done, but for the potential of what they might be able to do.” – Victor D. Manriquez, IPEMAN [37]

The practical benefits are obvious: faster processing times, higher first-time fix rates and increased employee productivity. At the same time, the valuable knowledge of experienced employees is secured – a decisive factor, especially in view of the fact that almost a quarter of all employees in the manufacturing industry were over 55 years old in 2020 [3]. In addition, knowledge management minimizes risks and errors by systematically documenting and sharing best practices. It also supports adherence to compliance requirements and thus reduces potential fines [36].

But how do you implement knowledge management effectively? A clear starting point is crucial: companies must first precisely analyze their knowledge requirements. It is important to understand what information is needed and how it is retrieved [24].

Successful approaches combine central knowledge databases, the integration of IoT data and the use of AI-supported tools to make the service future-proof.

As already described, shorter processing times and higher first-time resolution rates lead to sustainable success. Investing in knowledge management pays off: companies benefit not only from more efficient processes, but also from stronger customer loyalty and long-term competitive advantages. The decisive step is to establish knowledge management as a strategic priority now.

FAQs

How does knowledge management actually improve customer service and increase satisfaction?

How knowledge management improves customer service

Knowledge management plays a decisive role when it comes to making customer service more efficient and customer-oriented. With a central knowledge database, employees have quick access to structured and consistent information. This means shorter response times and more precise answers – a clear advantage for customer satisfaction.

In addition, well-organized knowledge management ensures uniform and reliable information. This consistency strengthens customer trust in your company. And trust not only leads to more satisfied customers, but also to closer, long-term customer loyalty. With a well-thought-out knowledge management strategy, you can not only make your customer service more efficient, but also exceed your customers’ expectations.

How do AI and IoT help to make service processes in knowledge management more efficient?

Artificial intelligence (AI) and the Internet of Things (IoT): a new era for knowledge management

Artificial intelligence (AI) and the Internet of Things (IoT) are changing the way service processes are carried out in knowledge management. The key lies in the provision of real-time data and the automation of workflows. AI can analyze huge amounts of data, recognize patterns and even make predictions to identify potential problems before they actually occur. This not only saves time, but also costs.

IoT devices play an equally important role here. They continuously provide data on the condition of machines and systems. This information enables more precise planning of maintenance work, faster response times and an overall more efficient way of working.

The combination of AI and IoT makes it possible to approach maintenance proactively. The result? Less downtime, more efficient processes and significantly increased customer satisfaction thanks to faster and more accurate services. AI and IoT are therefore not just technical innovations, but real game changers for knowledge management.

How can companies successfully introduce knowledge management and what hurdles need to be overcome?

Introducing successful knowledge management

In order to establish knowledge management effectively, companies should first define clear objectives and analyze the current state of knowledge in the company in detail. It can be helpful to form a team from different departments to coordinate the implementation. A well thought-out strategy for collecting, structuring and passing on knowledge forms the basis for sustainable success.

Of course, there are challenges that can make the process more difficult. These include resistance to change, a lack of technical resources or the absence of a culture of knowledge sharing. But these hurdles are not insurmountable. With early and open communication, targeted training and user-friendly tools, many problems can be mitigated. It is crucial to actively involve employees and clearly communicate the benefits of well-functioning knowledge management to them. A shared understanding of the value of knowledge creates the basis for long-term success.

Rethinking service processes: greater efficiency with IoT, AI and self-service

Find out how logicline’s extensions for Salesforce – especially for manufacturers of plant and machinery – can revolutionize your service processes with IoT, AI and self-service solutions. Find out more now and fully exploit service potential!