The intelligent installed base - how machine manufacturers are tapping into new service potential with digital machine files and AI agents

Let’s imagine a typical morning in service:

A technician opens three systems, searches for serial numbers, scrolls through PDFs, talks to colleagues on the phone. The customer is waiting. The machine has stopped. And nobody has an immediate overview.

Many machine manufacturers are familiar with this reality – from SMEs to global suppliers.

Yet this is precisely where one of the company’s greatest untapped assets lies: the installed base.

However, there is often a lack of transparency about machines in the field, their history, current performance and outstanding service requirements. This costs time, money and customer trust. And it prevents companies from developing a scalable, profitable service business from reactive deployments.

The solution: a digital machine file – linked to IoT data, service history, documentation and an AI agent that understands all this information.

Built on the Salesforce platform.

1. Why machine builders today know too little about their installed base

The customer’s machinery is the backbone of the after-sales business. However, the information is often scattered:

- Excel lists from the sales department

- ERP data for parts lists

- Service reports in the PDF archive

- IoT data in own platforms

- Know-how in the minds of individual technicians

VDMA studies have been showing this for years: Over 60% of all service information is unstructured and only a few companies have a complete, up-to-date overview of their installed base.

Typical questions such as:

- “What machines are at Freshoria and what condition are they in?”

- “Which systems have recurring problems?”

- “Which service contracts are expiring?”

lead to manual research, system changes and media disruptions.

Service managers, technicians, sales and management need very different information – but they all need the same data source.

2. The solution: the Digital Machine File on Salesforce

The digital machine file becomes the single point of truth.

It bundles all of a machine’s information – structured, versioned and contextualized.

Core components:

- Asset structure incl. machines, components, spare parts

- Serial numbers, locations, installation data

- Service history, materials, cost estimates

- Maintenance plans & contracts

- Telemetry data: Operating states, error codes, performance indicators

- Documentation, manuals, checklists

- DPP (Digital Product Passport)

- Access to remote support & IoT functions

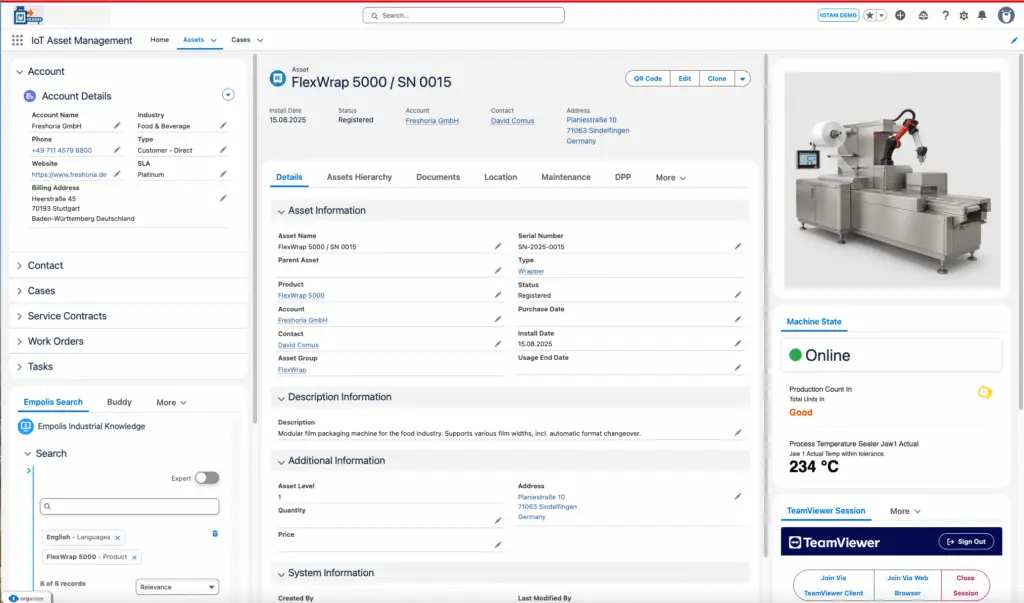

A screenshot from practice shows this clearly:

In the example of the FlexWrap 5000, you can see at a glance in the Salesforce interface:

- the machine status (“Online”)

- Process parameters such as temperature

- Production figures

- Contact and location data

- the associated service objects

- integrated tools such as TeamViewer or Empolis Knowledge

It is precisely this consistency that takes the machine file to the next level.

3. The foundation: a unified data model in the Lakehouse

For the machine file to realize its potential, it needs a consistent data model – regardless of where the data originally resides.

Four data worlds are connected via the Lakehouse:

Salesforce data

Customers, assets, contracts, cases, work ordersIoT telemetry

Sensor values, statuses, events, time seriesKnowledge Base

Diagnostic knowledge, step-by-step instructions, solution articlesHistorical data

Maintenance histories, version changes, trends over the years

Together, they create a 360° view – not just as a snapshot, but over the entire life cycle of a machine.

Partners such as GRAX can also be used to integrate change and history processes: Which values had changed and when? Which components have been replaced? Which errors occurred repeatedly?

All of this forms the basis for data-based service decisions, remote diagnostics and predictive models.

4. The game changer: an AI agent as an intelligent knowledge interface

The more data companies collect, the more crucial the question becomes:

Who makes this knowledge usable in everyday life?

This is where the AI agent comes into play – built on Salesforce Agentforce.

In contrast to classic chatbots, the agent does not access generic knowledge models.

It works with the structured data of its own installed base.

- It understands machines, serial numbers, hierarchies and telemetry.

- He evaluates cases, trends and patterns.

- He knows contracts, SLAs and maintenance plans.

- It combines knowledge from systems that were previously separate.

And above all: it responds in natural language.

No SQL, no dashboard building, no click paths.

Example from the field: Freshoria GmbH

The service manager of (exemplary) PackoTec GmbH asks a typical question:

“For the Freshoria account – what assets are in use there, what is the latest telemetry data, are there any critical cases and what service package could I offer the customer?”

The agent collects automatically:

- 32 assets from the PackoTec portfolio

- Telemetry with several critical states (including compressed air errors, sealing integrity problems, temperature deviations)

- 7 open HIGH-Priority Cases, all for the same machine (FlexWrap 5000)

- Patterns in downtimes and production losses

The agent summarizes, recognizes correlations and suggests specific measures – from immediate intervention to predictive maintenance.

Data-based knowledge results in a genuine recommendation for action.

This saves time, prevents downtime and increases service quality.

5. What is now possible: Concrete use cases & measurable business value

Proactive service

Question: “Which machines will soon exceed their maintenance intervals?“

Benefits: predictable deployment, fewer breakdowns, better SLA performance.

Retrofit campaigns

Question: “All customers with model X, built before 2020?“

Benefits: targeted campaigns, higher completion rates.

Troubleshooting in real time

Question: “Error code E-401 – cause, solution, future prevention?“

Benefits: shorter diagnosis times, fewer repeat errors.

Recognize sales opportunities

Question: “Which service contracts expire in Q1?“

Benefits: proactive renewals, higher service revenue.

Management reporting

Question: “How has the failure rate of model Y developed?“

Benefits: data-based product decisions, quality feedback in development.

The combination of machine files, telemetry, knowledge and AI creates systematic added value:

Search less. More action. Higher service quality. Scalable sales.

6. Why it all works – and why now

Three trends make this model particularly relevant:

1. Integration instead of isolated solutions

Service portals, IoT platforms, CRM, ticket systems:

What used to be separate now flows together in one data model.

2. AI needs structure

AI does not develop its strength with PDFs in the fileshare –

but with clean, unambiguous, versioned data records.

3. The shortage of skilled service staff

Teams are getting smaller, machines more complex.

What counts: fast diagnostics, less manual work, intelligent support.

logicline combines these points – with Salesforce as a platform and with expert knowledge of industrial service processes.

The result: clear data models, networked portals, IoT integration and AI agents that immediately provide practical answers. This basis makes service organizations scalable and resilient.

7. How companies can get started

Step 1: Structure the installed base

Serial numbers, locations, components, maintenance plans – neatly modeled in Salesforce.

Step 2: Integrate telemetry

Transfer time series, error codes, energy and process data to the Lakehouse.

Step 3: Link knowledge

Integrate Empolis or your own knowledge bases directly into cases, assets and error screens.

Step 4: Use AI agents

Train domain-specific agents on company data with Agentforce.

Step 5: Prioritize use cases

Proactive maintenance, campaigns, self-service, remote support – sort by business impact.

8. Outlook: From reactive operation to an intelligent service ecosystem

The digital machine file is a big step.

The AI agent next.

But the journey continues:

- Predictive maintenance through pattern recognition over the entire life cycle

- Autonomous recommendations for action: from advice to concrete action

- Seamless integration in Teams, Slack, mobile

- Self-service portals that answer customer questions independently

- Automated spare parts predictions

- Comparative analyses across fleets

Machine builders are thus transformed from troubleshooting companies into providers of intelligent services – reliable, scalable and profitable.

FAQs

How quickly can a digital machine file be introduced?

You can usually get started within a few weeks.

You start by structuring the installed base (machines, serial numbers, locations, documents) and later integrate telemetry and service histories. No big bang – modular expansion as required.

Do I necessarily need IoT data to use the AI agent?

No. The agent can already work with CRM, asset and case data. However,

IoT data significantly increases the benefits because the agent can then analyze statuses, trends and patterns in real time.

Will the AI agent replace service technicians?

No. It takes over the research, evaluation and consolidation of large amounts of data, but does not replace technical expertise.

technicians benefit from faster diagnosis, clear recommendations for action and less manual searching for information.

How do customers benefit from this?

Customers receive faster response times, more precise diagnostics and access to a self-service portal with their own machine file.

service becomes more transparent, easier to plan and more professional – a clear competitive factor in mechanical engineering.

Rethinking service processes: greater efficiency with IoT, AI and self-service

Find out how logicline’s extensions for Salesforce – especially for manufacturers of plant and machinery – can revolutionize your service processes with IoT, AI and self-service solutions. Find out more now and fully exploit service potential!