Making spare parts sales more efficient with B2B customer portals

Spare parts sales go digital. Machine and system manufacturers optimize their processes with modern B2B customer portals: Spare parts can be ordered around the clock, stock levels can be checked in real time and deliveries can be tracked. The advantages? Fewer errors, less effort and greater customer satisfaction.

This is about how customer portals are digitizing spare parts sales:

Important points:

-

Self-service portals enable simple ordering and real-time insights.

-

IoT data and predictive maintenance identify spare parts requirements at an early stage.

-

AI-supported recommendations reduce support requests and improve processes.

-

Salesforce & logicline offer scalable solutions for companies of all sizes.

A practical example shows that an automotive manufacturer digitized 80% of its processes in six months and reduced support tickets by 35%. Companies of all sizes benefit from modular solutions that can be flexibly tailored to their requirements. Now is the time to rethink spare parts sales.

Example from the industry - The digital service portal from KHS

The video shows the “KHS Connect” customer portal and demonstrates examples of functions that characterize modern spare parts stores. These include a digital parts catalog, price and availability display, order status and order templates – typical self-service modules that noticeably speed up after-sales processes. [Note: The KHS portal is not associated with us; we use it here solely as a good and illustrative industry example].

How to implement a B2B customer portal for spare parts sales

The introduction of a B2B customer portal for spare parts sales requires a structured approach based on the size of the company and the complexity of the products. While large companies often rely on scalable solutions with comprehensive integration options, medium-sized companies prefer a quick implementation with a focus on the most important functions.

Analyze business requirements and set goals

The first step is to take a close look at the current processes in spare parts sales. Where are the challenges? Are they manual ordering processes, a lack of transparency or high customer service costs? It is particularly important to analyze the product portfolio. Complex or multi-variant products require different functions than standardized spare parts.

The objective should include clearly measurable key figures. Examples include reducing the processing time for orders, increasing the proportion of online orders or improving customer satisfaction. A machine manufacturer was able to increase the proportion of online orders by 60% and reduce weekly support costs by 10 hours thanks to a self-service portal with an integrated product finder.

Involve all relevant departments at an early stage, including sales, service and IT. This will ensure that all requirements are taken into account and prioritized. It is important to differentiate between short-term successes and long-term strategic goals.

The right platform: Why Salesforce and logicline are a good choice

Once the objectives have been defined, the next step is to select a platform that optimally fulfills these requirements. The Salesforce Experience Cloud offers a flexible and secure basis for B2B portals in spare parts sales. It enables self-service functions, real-time inventory tracking and AI-supported recommendations – all GDPR-compliant.

logicline complements Salesforce with industry-specific solutions for machine and plant manufacturers. These include modules such as IoT asset management, digital machine files and spare parts web stores. These functions are seamlessly integrated into Salesforce. With the AI-based Agentforce–functions, companies can offer automated support and proactive problem solutions around the clock[1].

A major advantage is the modular expandability. Medium-sized companies can start with basic functions and expand the portal as required. Large companies, on the other hand, benefit from comprehensive customization and integration options right from the start.

Criterion | Group solution | Medium-sized business solution |

|---|---|---|

Scalability | Very high, extensive | Modular, step by step |

Product variety | Wide range of variants | Smaller portfolios |

Integration | ERP, IoT, asset management, AI | ERP, basic IoT, self-service |

Customization | Individual development | Standardized modules |

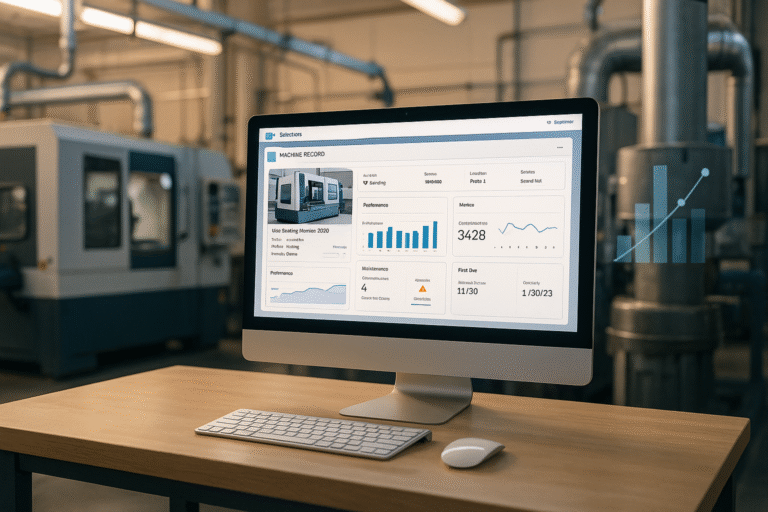

IoT Asset Management in Salesforce from logicline

Today, your customers expect self-service portals that offer them quick access to documentation or spare parts. At the same time, your internal processes, from resource planning to IoT-supported maintenance, need to mesh perfectly. With platform solutions such as Salesforce and our complementary modules, we create a seamless connection between your customers, your installed base and your teams.

Implementation: Integration, data migration and training

Once the platform has been selected, implementation takes place in several phases: Requirements analysis, solution design, integration, data migration and user training.

System integration is a key point here. The portal should be connected to ERP, IoT and asset management systems in order to use real-time data. Salesforce and logicline offer ready-made connectors and frameworks that simplify the integration process and ensure consistent data[1].

Proven methods are crucial for data migration. First, the data is checked to remove outdated or duplicate entries. Then the data fields are mapped between the old systems and the new portal. Automated tools with validation functions minimize errors, while test migrations in a sandbox environment ensure quality.

Effective user training is essential. Create target group-specific materials such as videos, guides and FAQs. Live webinars offer an additional opportunity to clarify questions directly. A user-friendly portal design, in-app help and self-service centers – supported by Salesforce Knowledge or Agentforce – make it easy to get started.

Core functions for effective spare parts trading

A successful customer portal is characterized by functions that improve the customer experience and at the same time make internal processes more efficient. Here are some of the central features that play a key role in this.

Self-service ordering and real-time inventory tracking

Self-service functions offer customers the opportunity to search for and order spare parts independently and around the clock. A spare parts web store with product search and reorder options forms the basis for this. Tools for precise spare parts identification, such as targeted search functions or a product finder, are particularly helpful in making it easier for customers to find the right parts for their machines.

Real-time inventory tracking provides additional transparency: customers can immediately see which parts are available and when they can be delivered. This reduces incorrect orders and makes planning easier. At the same time, customers can manage service tickets and orders independently. Supplementary documentation such as manuals or service reports support this process and reduce queries to support.

Another advantage is that the integration of IoT data takes the benefits of such portals to a new level by providing detailed insights into machine statuses.

IoT asset management and predictive maintenance

IoT connectivity makes it possible to use real-time data from machines and systems. Data such as operating statuses, meter readings or error codes flow directly into the portal and support proactive spare parts management and more precise warehouse planning. This gives manufacturers a complete overview of their installed base – from machines and components to maintenance schedules and their current status.

A digital machine file collects all relevant technical information, maintenance histories and live data in one central location. This makes it easier to identify service options and enables targeted planning of spare parts.

Predictive maintenance goes one step further: IoT data can be used to detect signs of wear and possible failures at an early stage. The system suggests suitable spare parts, often before unplanned breakdowns occur. This creates new sales opportunities that manufacturers can actively exploit.

logicline offers specialized solutions such as IoT asset management and digital machine files that can be seamlessly integrated into spare parts webshops. This allows machine data to be integrated directly into ordering processes, which makes the entire process more efficient[1][5].

Knowledge management and AI-supported recommendations

Another highlight is the integrated knowledge management, which helps customers to clarify technical questions independently. AI-supported systems provide comprehensive product information that can be used across teams. The result: customers find answers faster and can solve many problems themselves.

Empolis Service Express, a partner solution, offers seamless integration with Salesforce. With AI-supported search functions, service employees are guided directly to the information they need without any loss of time or media disruption.

In addition, Salesforce Agentforce offers AI-driven agents that automate service processes. They can process inquiries, make decisions and even optimize sales processes in spare parts stores, for example by automatically generating quotations.

The combination of knowledge management and AI-supported recommendations significantly reduces the workload of the support team. Customers can find the information or spare parts they need more quickly, while the support team can focus on more complex issues.

Use of the Salesforce platform and logicline solutions

Salesforce offers a powerful foundation with flexibility and scalability – combined with logicline’s expertise in spare parts sales, the result is an ideal solution for the digital B2B sector. With customizable approaches, logicline takes digital spare parts sales to a new level. The following section takes a closer look at logicline’s main solutions and their integration into the Salesforce platform.

logicline’s core solutions for machine and system manufacturers

For machine manufacturers, logicline offers a wide range of Salesforce-based tools that digitize service processes.

-

Self-service portals: These provide round-the-clock access to machine data and offer intelligent spare parts web stores. Spare parts can be precisely identified using specialized product finders.

-

IoT asset management: Here, machines are directly integrated into digital processes. Real-time data flows into digital machine files and provides a comprehensive overview of the installed base. The result? Predictive maintenance. Wear is detected at an early stage and suitable spare parts are automatically suggested.

-

Agentforce: The AI-supported solution from Salesforce automates routine tasks and makes smart recommendations. This allows orders to be processed, status queries to be answered and quotations to be created. An example from the automotive industry shows that an AI portal led to 80% more digital processing and 35% fewer support tickets.

Extended functionality through integration

logicline complements its solutions with versatile integration options that extend the functionality of the portal:

-

TeamViewerRemote diagnostics directly via the portal.

-

Empolis Service Express: Provides intelligent knowledge management that guides service agents quickly to the information they need.

The cooperation with Empolis shows impressively how such integrations can create added value:

“logicline impresses with its in-depth Salesforce expertise and excellent understanding of our Empolis products. Together, we have developed a Salesforce app that guides service agents directly to the information they need thanks to AI-supported search – without detours and media disruptions. The seamless integration into Salesforce offers our customers an optimized user experience and significantly more efficient processes. The partnership with logicline is extremely effective and has created a solution that offers real added value.” – Philipp Naujoks, Empolis

ERP systems for real-time inventories, PIM systems for product data management and IoT platforms for system monitoring can also be integrated.

Flexible customization for different company sizes and requirements

logicline relies on a modular approach that adapts solutions individually to company size and product type:

-

Medium-sized companies (SMEs): They benefit from portals with basic functions that can be implemented quickly. Implementation usually takes 3-6 months, or 2-4 months for simpler setups.

-

Corporations: Larger companies require more complex solutions, often with multilingual support and comprehensive ERP integrations. The implementation time here is 6-12 months.

The product range also influences the requirements: While standardized modules are sufficient for simple product lines, multi-variant portfolios require specialized product finders and configuration tools.

|

Criterion |

Medium-sized companies (SMEs) |

Group/Enterprise |

|---|---|---|

|

Implementation time |

3-6 months |

6-12 months |

|

Product range |

Manageable, fewer variants |

Wide range of variants |

|

Need for adjustment |

Standardized modules |

High level of customization |

|

Budget |

Lower, ROI-focused |

Higher, scale-oriented |

The Salesforce platform grows with the company’s requirements. Small portals can be expanded with additional functions as required without affecting the existing architecture.

Best practices and success factors

Successful customer portals are based on clear strategies, solid security measures and continuous development. Both technical and organizational aspects play a central role in this.

Data security and compliance with German regulations

In Germany, GDPR compliance is at the top of the priority list for B2B portals. Companies must ensure that all data processing procedures comply with strict data protection rules. This includes encrypted data transfers, secure storage of information and strict access rights to protect both business and personal data.

Adaptation to the German market requires more than just a translation. For example, portals should use euro prices, the DD.MM.YYYY date format and metric units of measurement [3,6]. Tools such as Salesforce Experience Cloud and solutions from logicline offer integrated GDPR functions and audit trails to ensure secure data management.

While large companies often require additional security measures such as ISO 27001 certifications, multi-factor authentication and complex access hierarchies, medium-sized companies rely on basic GDPR compliance and cost-effective solutions. Both benefit from the scalable security features of the Salesforce platform. Once security is guaranteed, the success of the portal should be measured using clearly defined KPIs.

Measuring success with key performance indicators (KPIs)

The right KPIs are crucial for evaluating the success of a portal. The relevant key figures include order processing time, error rates, online order rate, customer satisfaction (CSAT) and the reduction of support tickets. Salesforce dashboards and reports help to visualize these metrics, recognize trends and identify weak points.

Practical results show how effective such approaches can be: Mechanical engineering portals recorded 60% more online orders and reduced the support effort by 10 hours per week. Automotive portals achieved 80% digital processing and reduced the number of support tickets by 35%.

|

KPI category |

Measured variable |

Target value |

Measuring interval |

|---|---|---|---|

|

Efficiency |

Online order rate |

>60 % |

Monthly |

|

Service |

Support ticket reduction |

-35 % |

Quarterly |

|

Quality |

Order error rate |

<2 % |

Weekly |

|

Satisfaction |

CSAT score |

>4,5/5 |

Monthly |

Regular reviews of the KPIs promote further development. Many portals reach rollout within 4-6 months and achieve a positive return on investment from the 6th-8th month.

Continuous improvement and user feedback

In addition to security aspects and KPIs, user feedback is a key factor for long-term optimization. Feedback forms, surveys and analysis tools provide valuable insights into user-friendliness and desired functions. Salesforce offers integrated feedback mechanisms, while logicline’s AI-powered analytics tools help to identify weaknesses and prioritize improvements [1].

Change management and comprehensive training are crucial to ensure user acceptance. Early involvement of key stakeholders, user acceptance tests (UAT) and clear training programs ensure a smooth transition. Intuitive interfaces, simple navigation and self-service functions reduce the number of support requests and increase user satisfaction.

Iterative further development based on agile methods is the key. The portal remains relevant through regular feedback, transparent communication about updates and the adaptation of functions to new requirements. AI-supported systems also offer round-the-clock support and personalized experiences, which further increases customer satisfaction.

Regular audits and penetration tests ensure that the portal remains secure and compliant in the long term. Modern B2B portals achieve an average 60% higher usage rate compared to older systems – proof of how effective a well-thought-out strategy can be.

Portal Features vs. Business Requirements Comparison

Based on the core functions described above, the specific requirements of different company sizes are compared here. The portal functions required depend heavily on the size of the company and the complexity of the products offered. While medium-sized companies with standardized products often prefer simple self-service portals, corporations with a broad product range require significantly more complex systems.

Medium-sized companies with a manageable product range benefit from standard solutions that are easy to implement. A self-service portal that offers an integrated product finder and real-time inventory, for example, can already bring about significant increases in efficiency. The Salesforce Experience Cloud offers modular solutions for this, which can be adapted by logicline specifically for mechanical and plant engineering. Typical requirements are described in detail below using various scenarios.

Companies with a wide variety of products, on the other hand, require advanced functions such as AI-supported product finders, IoT asset management and complex ERP integrations. A real-life example: an automotive manufacturer with over 50,000 spare parts was able to digitize 80% of its processes and reduce the number of support tickets by 35% by integrating an SAP/PIM system. Such projects require the full use of the Salesforce platform in conjunction with an Agentforce integration.

|

Portal function |

Medium-sized companies (simple products) |

Medium-sized companies (complex products) |

Group (simple products) |

Group (complex products) |

|---|---|---|---|---|

|

Self-service ordering |

High (simple operation) |

High (with product finder) |

High (multi-user management) |

Essential (AI-supported search) |

|

Real-time inventory |

Medium (basic data) |

High (availability critical) |

High (multi-location) |

Essential (ERP/PIM integration) |

|

IoT integration |

Optional |

Medium (predictive maintenance) |

High (asset management) |

Essential (digital machine file) |

|

AI recommendations |

Low (FAQ sufficient) |

Means (product recommendations) |

High (automation) |

Essential (Agentforce integration) |

|

Knowledge management |

Medium (standard documentation) |

High (technical details) |

High (multilingual) |

Essential (AI-supported search) |

|

Customizability |

Low (standard solutions) |

Medium (modular extension) |

High (Corporate Design) |

Essential (individual workflows) |

As shown in the table, the requirements for functions such as IoT integration and AI-supported recommendations vary considerably depending on the size of the company and product complexity. Especially for companies with a broad product range, digital machine files and intelligent product finders are crucial for minimizing incorrect orders. This is where logicline’s specialized tools in the Salesforce ecosystem come into play, such as the integration of Empolis Service Express for advanced knowledge management.

There are also significant differences in terms of implementation time and costs: While medium-sized companies can often implement standard solutions within 4-6 months, large corporations usually need 8-12 months to fully integrate and customize their complex portals. However, the modular architecture of the Salesforce platform makes it possible to start with basic functions and gradually expand the portal as required. This allows companies to flexibly adapt their solution to increasing requirements.

FAQs

How can a medium-sized company efficiently introduce a digital B2B customer portal for spare parts sales?

A medium-sized company can make the process of introducing a digital B2B customer portal efficient if certain key factors are taken into account. A strong customer focus plays a central role here: the portal should be easy to understand and user-friendly, with a focus on functions such as a simple search for spare parts and an uncomplicated ordering process.

An agile approach makes it possible to react flexibly to new requirements and drive the development process forward more quickly. It makes sense to work in small steps and obtain feedback from actual users at an early stage in order to continuously improve the portal.

The use of a platform such as Salesforce also offers the opportunity to use modern technologies such as IIoT integration and AI-supported functions. These can automate processes and optimize the customer experience at the same time. This not only makes the portal efficient, but also future-proof in the long term.

What advantages does IoT integration in digital spare parts portals offer, especially for predictive maintenance?

The integration of IoT technology into digital spare parts portals opens up completely new possibilities for monitoring machines and systems in real time. Operating data is continuously collected and analyzed in order to precisely assess the condition of the equipment. The best thing about it? Problems can be identified at an early stage so that maintenance work can be planned before unplanned downtime occurs.

The result is clear: less downtime, increased efficiency and a smoother supply of spare parts. For companies, this not only means lower costs, but also improved customer satisfaction thanks to trouble-free operations.

What steps are necessary to introduce a digital customer portal in Germany in compliance with the GDPR?

A few key steps are necessary to bring a digital customer portal into compliance with the GDPR. Users must be informed clearly and comprehensibly about how their data is processed and, if necessary, their express consent must be obtained. Care should always be taken to only collect and process the data that is actually required.

Technical security precautions also play a crucial role. These include encryption techniques and access restrictions to protect the data from unauthorized access. If data is passed on to external service providers, an order processing contract must be concluded in accordance with Article 28 GDPR. It should also be easy for users to exercise their rights – such as the right to access, rectify or erase their data.

If the processing of the data poses an increased risk, a data protection impact assessment is required. In addition, the appointment of a data protection officer is necessary if this is required by law. With these measures, you ensure that your customer portal meets the GDPR requirements and that your users’ data is managed securely.

Rethinking service processes: greater efficiency with IoT, AI and self-service

Find out how logicline’s extensions for Salesforce – especially for manufacturers of plant and machinery – can revolutionize your service processes with IoT, AI and self-service solutions. Find out more now and fully exploit service potential!