What if your machines could talk to you?

What if they could warn you days in advance that they are overheating, vibrating abnormally or consuming too much power? This is no longer science fiction, but the reality of the Industrial Internet of Things (IIoT), a central component of Industry 4.0. Predictive maintenance is a core aspect of this development – and that is exactly what this article is about.

Predictive maintenance with IoT enables production companies and machine manufacturers to identify problems before they lead to breakdowns, delays or damage. You not only save costs, but also optimize the efficiency and uptime of machines. Find out how predictive maintenance works, the technologies behind it and how companies in industries such as automotive, energy and manufacturing are already saving millions through this innovative method.

Predictive maintenance & IoT

What is predictive maintenance and how does it work?

Predictive maintenance represents a revolution in maintenance strategy. Unlike reactive or preventive maintenance, the aim here is to determine the perfect time for maintenance measures – neither too early nor too late. This is made possible by the continuous monitoring of machines and the intelligent analysis of sensor data.

The data flow for predictive maintenance

From the factory floor to data-driven decisions, predictive maintenance follows a clear workflow:

-

Smart sensors

Smart sensors form the basis. They continuously measure parameters such as temperature, vibration, current and pressure. This raw data is fed directly into the system. -

Edge devices

Edge devices such as industrial gateways or edge PLCs (programmable logic controllers) process the data locally. They filter out irrelevant information, detect anomalies at an early stage and enable rapid reactions on site. -

Cloud platforms

The filtered data is sent to the cloud, where it is stored and analyzed centrally. This is where dashboards, alerts and reports on historical trends are created. This is also the basis for IoT asset management and a view of the installed base. -

Artificial intelligence and machine learning

Cloud-based AI engines analyze patterns in the data and detect deviations. Over time, these models become increasingly precise and reduce false alarms.

Which technologies drive predictive maintenance?

Behind every successful predictive maintenance is a combination of high-performance technologies. The most important building blocks are

1. MQTT (Message Queuing Telemetry Transport)

A lightweight protocol that allows sensors and devices to send data efficiently even with low network capacities. It ensures reliable real-time updates from machines to servers.

2. OPC-UA (Open Platform Communications Unified Architecture)

A flexible and secure communication standard that enables seamless data transmission between machines from different manufacturers – essential for building scalable IIoT systems.

3. edge computing

Edge computing reduces dependence on the cloud by processing data locally. This allows devices to react quickly to anomalies, such as abnormal vibrations in an engine.

4 AI and machine learning

By analyzing historical data – such as vibrations, temperature peaks or power consumption – AI models detect deviations and predict potential failures.

IoT Asset Management in Salesforce from logicline

Today, your customers expect self-service portals that offer them quick access to documentation or spare parts. At the same time, your internal processes, from resource planning to IoT-supported maintenance, need to mesh perfectly. With platform solutions such as Salesforce and our complementary modules, we create a seamless connection between your customers, your installed base and your teams.

How is predictive maintenance implemented in practice?

Predictive maintenance is already showing clear benefits in various industries. Here are some examples of applications:

1st automotive industry

Robotic arms for welding and painting are crucial for production. IoT sensors monitor temperature and vibration to detect wear at an early stage and avoid expensive production downtime.

2. industrial production

In CNC machining centers, spindle failure can lead to significant production losses. By monitoring bearing temperatures and vibrations, companies can plan maintenance optimally.

3. energy sector

Wind turbines and transformers are often located in places that are difficult to access. IoT sensors track load, temperature and pressure so that technicians can intervene before a failure occurs.

4. oil and gas industry

Pipelines and compressors are critical infrastructure. By monitoring flow, vibration and pressure, potential blockages or leaks can be detected at an early stage.

The results in these scenarios are impressive: fewer surprises, fewer breakdowns and more informed maintenance decisions.

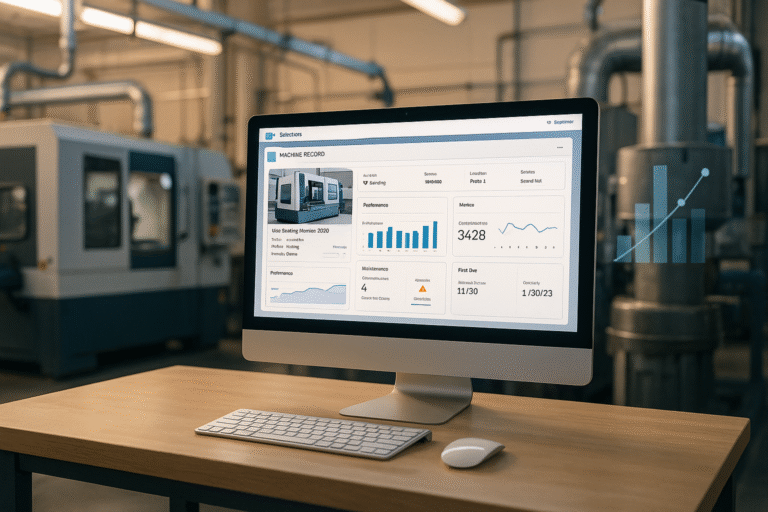

The role of dashboards in predictive maintenance

Massive amounts of data alone are not enough – the benefits of predictive maintenance can only be fully exploited through clear visualization. Dashboards are the central tool:

- Real-time monitoring: Live dashboards show the status of machines (e.g. motor temperature, vibration, current flow) and enable quick action.

- Historical trends: Long-term analyses help to identify recurring problems and plan maintenance better.

- Smart alerts: Alerts based on patterns instead of fixed thresholds minimize false alarms and increase relevance.

- Customization: Dashboards can be customized according to the target group – from technical details for maintenance teams to ROI data for managers.

Security aspects in the IIoT

As connectivity increases, so do the security risks. The protection of IIoT systems is therefore essential:

- Data encryption: All data transmissions should be encrypted.

- Network segmentation: Critical systems must be isolated from external networks.

- Access management: Only authorized users should have access to devices and dashboards.

- Secure protocols: Standards such as OPC-UA with TLS encryption offer additional security.

The introduction of predictive maintenance: a roadmap

A step-by-step approach minimizes risks and maximizes implementation success:

Pilot project: Start with a single machine or production line.

Data collection: Sensors collect data over weeks to establish a baseline.

Analysis: AI models analyze the data and identify patterns.

Scaling: Extend the implementation to additional machines or locations.

ROI tracking: Measure savings and improvements in uptime.

Training: Make sure your team understands the dashboards and can respond to alerts.

Conclusion and most important future outlook: The next generation of smart factories

The future of predictive maintenance promises even greater possibilities:

Digital twins: Virtual machine models simulate future performance.

5G connectivity: ultra-flat real-time data transmission for huge systems.

Self-optimizing systems: AI will not only be able to predict errors, but also maximize efficiency autonomously.

Key Takeaways

Predictive maintenance reduces downtimes and maintenance costs.

By using IIoT data, problems can be detected before they occur.Technologies such as sensors, edge devices and AI work together.

They enable fast reactions and precise analyses.Dashboards make data usable.

They offer real-time monitoring, historical trends and smart alerts.A step-by-step approach minimizes risks.

Start small, scale up and train your team.Security is essential.

Encryption, network isolation and access control protect your IIoT system.

Predictive maintenance is more than just a technical advance – it is a paradigm shift in industrial maintenance. This applies to machine operators and manufacturers alike. By predicting problems, companies can not only save costs, but also revolutionize their processes and further develop their business models. The journey to a fully networked future has only just begun.

Rethinking service processes: greater efficiency with IoT, AI and self-service

Find out how logicline’s extensions for Salesforce – especially for manufacturers of plant and machinery – can revolutionize your service processes with IoT, AI and self-service solutions. Find out more now and fully exploit service potential!