Machine sales under pressure - exploiting opportunities in existing stock

The world of machinery manufacturers is changing: competitors from Asia are offering machines of the same quality at significantly lower prices. Traditional new sales are coming under increasing pressure. At the same time, the potential of the installed base – i.e. machines that have already been delivered and are in operation – is still not being systematically utilized in many places.

This is precisely where a decisive lever lies: spare parts, maintenance, retrofits, extensions or even warranty and service contracts offer enormous sales opportunities. If you know your installed base, you can generate targeted service revenue from it – efficiently, predictably and with strong growth.

According to studies, the service potential of the installed base is often two to three times the annual turnover of new machines. However, this potential often remains untapped due to a lack of data or inefficient processes.

Tip: Make targeted use of this lever and expand your installed base into a systematic service business.

Solutions for service strategies of machinery manufacturers

No strategy without data: Why transparency is crucial

A structured data basis is essential for the success of service strategies. However, many companies lack a complete overview of their installed base: Which machines are in use where? How old are they? What condition are they in? And what services have been carried out in the past?

Without consistent machine data, it is impossible to plan maintenance, forecast spare parts requirements or offer customized service packages. This is exactly where digitalization comes into play:

Three steps to digital transparency:

Record inventory data: Systematically record and digitize serial numbers, location data, operating times and maintenance histories.

Establish IoT connection: Sensors on machines enable real-time recording of status data (temperature, vibration, utilization, etc.).

Introduce a central data platform: Systems such as Salesforce enable the consolidated presentation and evaluation of all customer and machine data.

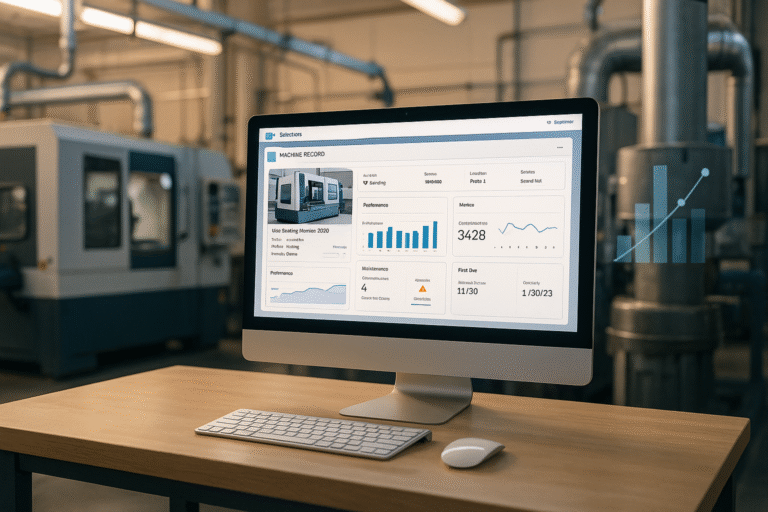

With a digital service platform such as Salesforce, this data can be brought together centrally and used intelligently – from usage history to customer contact. This creates a digital machine file, a digital twin of the installed base that serves as the basis for service offers.

From service mindset to corporate strategy

Service must become a top priority. A strategically oriented service approach requires more than technical excellence: it requires a rethink throughout the entire company. Instead of viewing service as a cost center, it should be seen as a profitable growth driver.

This includes:

- Establish a service mindset: All departments – from sales to technology to management – must understand service as a central business area.

- Adapt incentive systems: Target agreements and KPIs should take service turnover, customer satisfaction and repurchase rates into account.

- Digitize service processes: Efficiency and scalability can only be achieved through automated processes, digital customer interfaces and integrated platforms.

Exemplary modules of service strategies for machinery manufacturers:

- Spare parts identification via portal: customers identify the parts they need using an online tool and order them directly.

- Retrofit offers based on machine usage: Automated advice on possible upgrades.

- Service level agreements with real-time data: Contracts based on usage and condition, monitored automatically.

More on this in the article: Service as a profit center: Interview with Markus Fournell

IoT Asset Management in Salesforce from logicline

Today, your customers expect self-service portals that offer them quick access to documentation or spare parts. At the same time, your internal processes, from resource planning to IoT-supported maintenance, need to mesh perfectly. With platform solutions such as Salesforce and our complementary modules, we create a seamless connection between your customers, your installed base and your teams.

Digital platforms as enablers for the installed base

The technological implementation of a service-centric strategy can only succeed with a scalable, integrative and customizable platform. The Salesforce platform offers precisely these possibilities:

Why Salesforce?

360° customer view: All relevant information on customers, machines, contracts and service cases can be accessed centrally.

IoT asset management: status data and machine usage can be recorded and evaluated live.

AI-supported service automation: Recurring processes such as ticket assignments, spare parts suggestions or scheduling are automated using artificial intelligence.

Integration of partner solutions: Tools such as TeamViewer (remote support) or Empolis Service Express (knowledge database) can be integrated directly.

logicline is an official Salesforce partner with a focus on mechanical engineering and supports manufacturers in the implementation of individual service platforms – from architecture and integration to product development.

Monetization potential: How to generate predictable service revenue

The digitalization of the installed base opens up numerous new revenue models. It is important to structure these systematically and adapt them to the life cycles of the machines.

| Potential | Potential Description | Example |

|---|---|---|

| Spare parts sales | Recognize demand at an early stage and offer it automatically | Intelligent repeat orders via customer portal |

| Retrofit offers | Play out personalized upgrades and modernizations | Retrofit campaign for machines older than 5 years |

| Predictive maintenance | Offer maintenance based on condition data | Predictive maintenance in case of temperature rise |

| Equipment-as-a-Service | Do not sell machines, but provide them as a service | Monthly payment instead of purchase |

Conclusion: The installed base as a strategic growth lever

Those who think strategically about service not only exploit the full potential of their existing customers, but also gain a sustainable competitive advantage. Digital transparency, modern platforms and a service-oriented mindset allow you to build long-term customer loyalty and generate predictable sales.

Essential building blocks:

- Digital recording of the installed base

- Integration of IoT and predictive maintenance

- Development of scalable service platforms

- Development of new business models such as EaaS

logicline offers the necessary experience, technology and industry specialization to successfully shape this change.

FAQs

What exactly does "installed base" mean?

The installed base comprises all of a manufacturer’s machines and systems that are already in use at the customer. It represents an important lever for generating additional sales through targeted service offers such as spare parts, maintenance or upgrades – regardless of the new machine business.

How do I start digitizing my service processes as machinery manufacturer?

Start with a structured inventory of the installed machines. Integrate IoT data to record the condition and rely on central platform solutions such as Salesforce to bundle and automatically process data from service, sales and customer contact.

What role does predictive maintenance play in a service strategy?

Predictive maintenance makes it possible to detect failures at an early stage and take targeted preventative measures. This increases machine availability, service calls are planned more efficiently and customer relationships are strengthened through reliability.

How does logicline provide concrete support for implementation?

logicline supports companies in the mechanical engineering sector from strategy development and process digitalization to implementation on the Salesforce platform – including IoT connection, customer portals, knowledge management and automation with AI agents.

Rethinking service processes: greater efficiency with IoT, AI and self-service

Find out how logicline’s extensions for Salesforce – especially for manufacturers of plant and machinery – can revolutionize your service processes with IoT, AI and self-service solutions. Find out more now and fully exploit service potential!